Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Products

Model No.: SYH

Brand: Jirui

Barrel Volume (L): 1000

Material: Sus304, Sus316, Sus316l

Application: Medicine Processing, Chemicals Processing, Food Processing, Powder

Old And New: New

Place Of Origin: China

Warranty Period: 1 Year

Core Selling Point: Automatic

Out-of-warranty Service: Video Technical Support, Online Support, Spare Parts

Applicable Industry: Manufacturing Plant

Marketing Type: New Product 2020

Mechanical Test Report: Provided

Video Factory Inspection: Provided

Core Component Warranty Period: 1 Year

Core Components: Motor

Warranty: 1 Year

Video Outgoing-inspection: Provided

Warranty Of Core Components: 1 Year

Key Selling Points: Competitive Price

Function: Mixer Blender

Material Processed: Chemicals, Food, Medicine

Place Of Origin: Jiangsu, China

Brand Name: Jirui

Applicable Industries: Manufacturing Plant, Food & Beverage Factory, Farms, Energy & Mining, Pharmaceutical industries

Packaging: Standard export wooden cases

Productivity: 10 sets/month

Transportation: Ocean,Land

Place of Origin: China

Supply Ability: 10 Sets/Month

Certificate: CE, CCC

Port: shanghai port

Payment Type: T/T,L/C

Incoterm: FOB,CFR,CIF,FCA

Description of Mixing Machine for Pharmaceutical Product:

The three dimensional movement mixer that is convenient to discharge, puts materials into the inside of the feeding pipe after opening the feeding cover, and the materials reach the inside of the mixing tank along the feeding pipe, and then close the mixing tank, and the mixer body starts to work at this time. The whole mixing tank rotates to make the material in the mixing tank mix with the rotation of the mixing tank. After the mixing time is reached, the discharge valve is opened, and the material reaches the collection box through the discharge pipe. The bottom discharge of the tank can increase the distance from the collection box and prevent the material from pouring out of the collection box. After some materials stick to the inner wall of the mixing tank, the electric push rod is driven to work, and its output shaft starts to move downward, driving The connecting plate and the scraper sleeve move down to achieve the purpose of convenient discharge.

Principle:

When it works, the mixer is provided with three-dimensional movement, and carries out revolution and rotation. The mixer has powerful turbulent action to accelerate material flowing and dispersing and makes turning and translational movement to conquer the impact of centrifugal force, so that gravity segregation and agglomeration will not occur in the materials, there is no dead corner, and even mixing is ensured.

Features:

●The mixing machine is provided with three-dimensional movement so that the materials complete the process of mutual mixing from the agglomeration status to dispersion status under the actions of flowing, shearing, translational movement and dispersion, even mixing of materials is ensured and the evenness reaches 99.9%. In ordinary mixers, the materials only make simple dispersion and agglomeration movement in the vessel, which is featured by low efficiency and bad mixing quality.

●With short mixing time and high efficiency, the effective loading rate of the vessel reaches 80%. (The rate of ordinary mixers is only 40%.)

●The Powder Mixer Machine is low and does not have special requirements for plants, so that investment in basic construction is reduced.

●The mixing barrel and machine body driving part can adopt partition installation to meet GMP requirements.

●For the SYH-2 model mixer, mixing vessels of various shapes can be placed in the mixing barrel for mixing with convenient use.

●Stepless speed adjustment can be realized to facilitate material loading and unloading.

●It is featured by long service life and low noise.

●Vacuum feeding and lifting machine feeding are available.

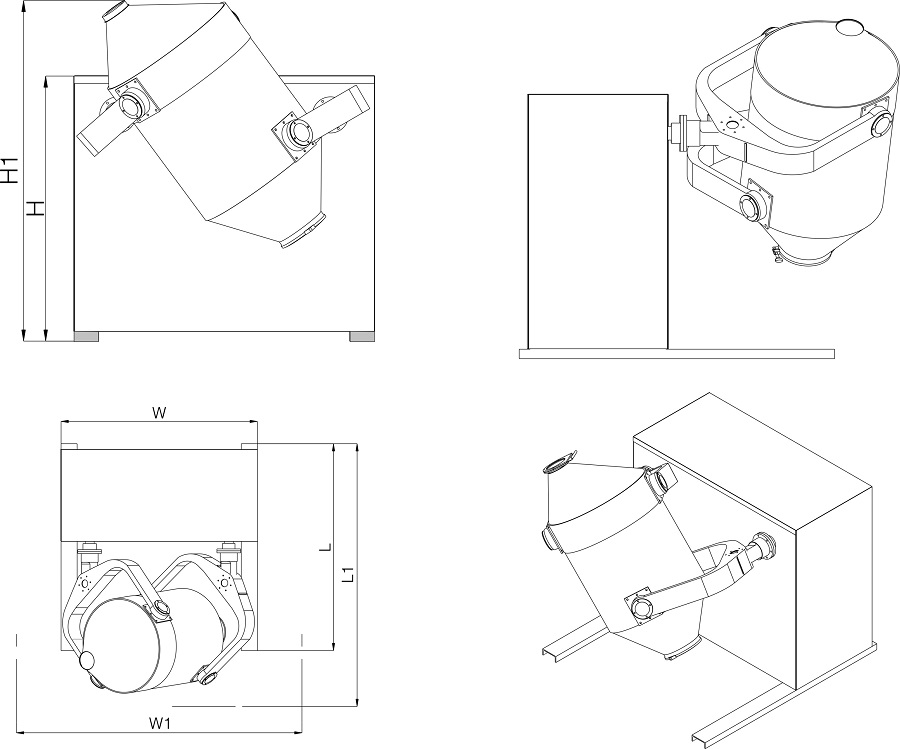

Drawing:

Product Categories : Mixing Machine > High Efficiency Three Dimensional Movement Mixer

Home > Products > Mixing Machine > High Efficiency Three Dimensional Movement Mixer > Mixing Machine for Chemical Pharmaceutical Food Product

Send Inquiry

Ms. Susan

Tel:86-0510-86184255

Fax:

Mobile Phone:+8615961650796

Email:susanliu35@gmail.com

Address:No.8 Dongmeng Road, Dongmeng Technology Zone, Nanzha Town, Jiangyin , Wuxi, Jiangsu

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.