Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Products

Model No.: BXFG

Brand: Jirui

Species: Fluid Bed Drying Equipment

Application: Medicine Processing, Chemicals Processing, Food Processing

Old And New: New

Place Of Origin: China

Core Selling Point: Energy Saving

Warranty Period: 1 Year

Out-of-warranty Service: Video Technical Support

Applicable Industry: Food &Amp; Beverage Factory

Marketing Type: Ordinary Product

Mechanical Test Report: Provided

Video Factory Inspection: Provided

Core Component Warranty Period: 1 Year

Core Components: Bearing, Pump, Motor

Evaporation Capacity (kg/h): 10

Heat Source: Steam Heating

Material: Sus304, Sus316, Sus316l

Condition: New

Warranty: 1 Year

Key Selling Points: Automatic

Place Of Origin: Jiangsu, China

Brand Name: Jirui

Applicable Industries: Manufacturing Plant, Food & Beverage Factory, Farms, Energy & Mining, Pharmaceutical industries

Machinery Test Report: Available

Type: Drying Equipment

Packaging: Standard Wooden Case or Stretch Flim.

Productivity: 10 sets/month

Transportation: Ocean

Place of Origin: China

Supply Ability: 5 Set/Sets per Month

Certificate: CE

Port: Shanghai Port

Payment Type: T/T,L/C

Incoterm: FOB,CFR,CIF,EXW

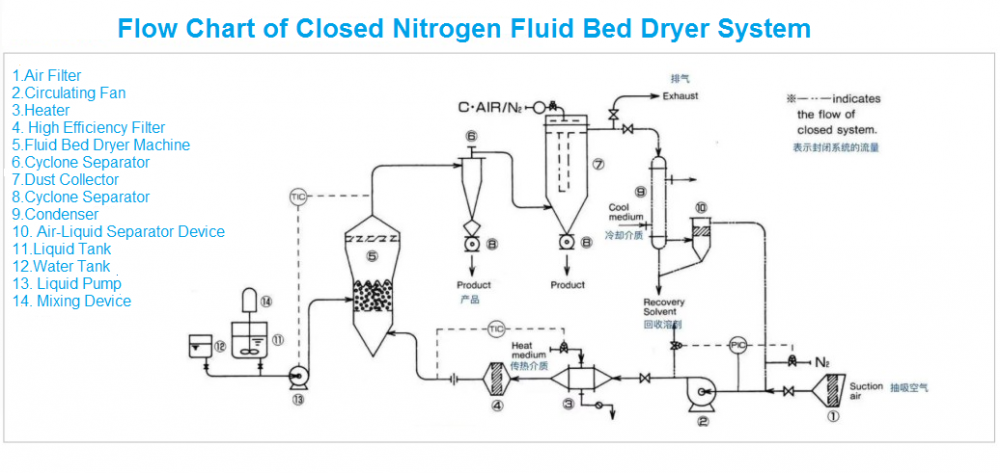

Principle of Industrial Fluid Bed Drying Machine:

First step,using the blower to inlet the filtered nitrogen, then heat the nitrogen to a required temperature. The material was added by the star valve to the dryer machine. The bulk material is broken through the breaking device, and the material is fed while drying. In the drying process, the wet material is dried in the dryer, and the hot and humid air with a few micro powder (below 2um) pass through the bag filter. It is the latest Powder Dryer Machine.

Drying time:

The drying time depends on various factors such as physical properties of material, moisture content, type of moisture ( free or inherent of water or crystallization) drying temperature etc. For example, the crystalline product can be dried faster than amorphous product containing same percentage of moisture at same temperature. Pharmaceutical granules & powder having approximately 20% to 25% moisture can be easily dried. Fluid bed dryer are normally supplied either with electric heating or with steam heating. However hot water/ hot oil circulation system can also be installed.

Technical Parameter:

| Total Volume (L) | 12 | 22 | 100 | 220 | 420 | 670 | 1000 | 1500 |

| Steam Consume (KG/Batch) | 12 | 23 | 70 | 140 | 211 | 282 | 366 | 465 |

| Fan Power (KW) | 2.2 | 4 | 5.5 | 11 | 18.5 | 22 | 30 | 45 |

| Mxing Powder (KW) | 0.55 | 0.75 | 1 | 1.5 | 2.2 | 2.2 | 3 | 3 |

| Temperature (℃) | Adjustable from ambient to 120℃ | |||||||

| Final Moisture Content(%) | ~0.2 | |||||||

| Noise (DB) | ≤75 | |||||||

| Recovery Rate(%) | >99 | |||||||

Product Categories : Drying Machine > Fluid Bed Dryer

Home > Products > Drying Machine > Fluid Bed Dryer > Industrial Fluid Bed Dryer Machine

Send Inquiry

Ms. Susan

Tel:86-0510-86184255

Fax:

Mobile Phone:+8615961650796

Email:susanliu35@gmail.com

Address:No.8 Dongmeng Road, Dongmeng Technology Zone, Nanzha Town, Jiangyin , Wuxi, Jiangsu

Related Products List

Mobile Site

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.