Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Products

Brand: Jirui

Place Of Origin: China

Status: New

Types Of: Drying Machine

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Marketing Type: New Product 2020

Core Component Warranty Period: 3 Years

Core Components: Motor, Gear, Pump, Bearing

Application: Liquid

Warranty Period: 1 Year

Core Selling Point: Long Service Life

Out-of-warranty Service: Video Technical Support, Spare Parts, Online Support

Applicable Industry: Manufacturing Plant, Food &Amp; Beverage Factory

Packaging: Wooden Case or Plastic Film

Transportation: Ocean,Land

Payment Type: L/C,T/T

Incoterm: FOB,CIF,CFR,EXW

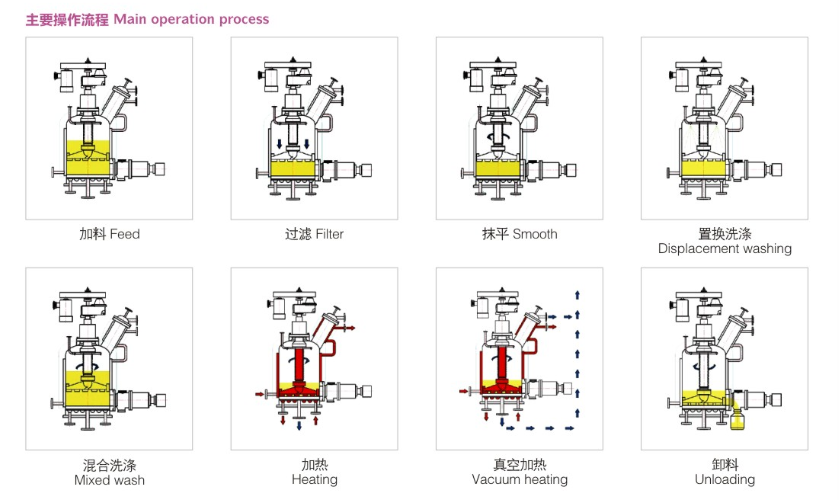

How an Agitated Filter Washing Drying Equipment Work:

The first step: move the material to the filtering washing drying equipment. Customer should choose the suitalbe filter size. The common rule is the height of solid not more than the mixing scope. The second step: Using pressure or vacuum to let liquid through solid. The third step: Customer can washing the material using liquid. And the last step: Drying material.

Important Advantages:

Main operation process:

Product Categories : Drying Machine > Filter Dryer

Home > Products > Drying Machine > Filter Dryer > Agitated Filter Washing Vacuum Drying Machine

Send Inquiry

Ms. Susan

Tel:86-0510-86184255

Fax:

Mobile Phone:+8615961650796

Email:susanliu35@gmail.com

Address:No.8 Dongmeng Road, Dongmeng Technology Zone, Nanzha Town, Jiangyin , Wuxi, Jiangsu

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.