Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Products

Model No.: SZG

Brand: Jirui

Species: Vacuum Drying Equipment

Application: Medicine Processing, Chemicals Processing, Food Processing

Old And New: New

Place Of Origin: China

Warranty Period: 1 Year

Out-of-warranty Service: Video Technical Support

Applicable Industry: Food &Amp; Beverage Factory

Marketing Type: Ordinary Product

Mechanical Test Report: Provided

Video Factory Inspection: Provided

Core Component Warranty Period: 1 Year

Core Components: Motor, Bearing, Pump

Evaporation Capacity (kg/h): 20

Heat Source: Steam Heating

Material: Sus304, Sus316, Sus316l

Type: Rotary Drying Equipment

Condition: New

Brand Name: Jirui

Power: 0.75kw, 0.75kw

Dimension(L*W*H): Varied

Key Selling Points: Automatic

Warranty: 1 Year

Applicable Industries: Manufacturing Plant, Food & Beverage Factory, Farms, Energy & Mining, Pharmaceutical industries

Showroom Location: None

Machinery Test Report: Not Available

Video Outgoing-inspection: Provided

Warranty Of Core Components: 1 Year

Heating Source: hot water or low pressure steam or heat transfer oil

Total Volume: 100l

Work Volume: 50L

Heating Area: 1.16㎡

Rotation Speed: 6~9rpm

Rotation Height: 1810mm

Design Pressure In The Tank: -0.09~0.096Mpa

Place Of Origin: Jiangsu, China

Voltage: 380V

Weight (KG): 1000

Packaging: Standard Export Wooden Case or Plastic film.

Productivity: 10 sets/month

Transportation: Ocean

Place of Origin: China

Supply Ability: 10 Set/Sets per Month

Certificate: CCC, CE

Port: shanghai port

Payment Type: Western Union,T/T,L/C,MoneyGram

Incoterm: FOB,CFR,CIF,EXW

Temperature change of The Chemical Products Double Cone Dryer:

Depending on the physical properties of the material, an appropriate temperature can be selected. Usually, the variable temperature drying method can be used. The temperature is low in the initial stage of drying, and the temperature is gradually increased to increase the drying rate.

When vacuuming and heating are started, the drying speed is slow. When the material is heated above the vaporization temperature of water, the drying speed will suddenly increase. The material is heated to the vaporization temperature under the corresponding pressure within the allowable temperature range and vaporized in large quantities. The temperature remains constant, the added heat is used for vaporization heat and various heat losses, and the vacuum system continuously discharges the vaporized steam to maintain the pressure difference between the evaporation surface and the space, so that the drying continues. When the moisture content of the material is reduced to a certain level, the water evaporated from the material is reduced. When the heating amount remains unchanged, the temperature of the material begins to rise, the pressure difference between the evaporation surface and the space decreases, and the drying enters the deceleration stage. The drying rate gradually decreases until zero.

Applications:

This Drying Machine is suitable for concentration, mixing and drying of powder, granular and fibrous materials in such industries as chemical industry, medicine, food, etc., and materials that require low temperature drying(such as biochemical products), and is more suitable for drying of materials that are easy to oxidize, volatize, heat sensitive materials, irritant and poisonous materials, and materials in which breaking of crystals is not allowed. The rotary cone vacuum dryer is an important industrial dryer machine, lots of customers choose it.

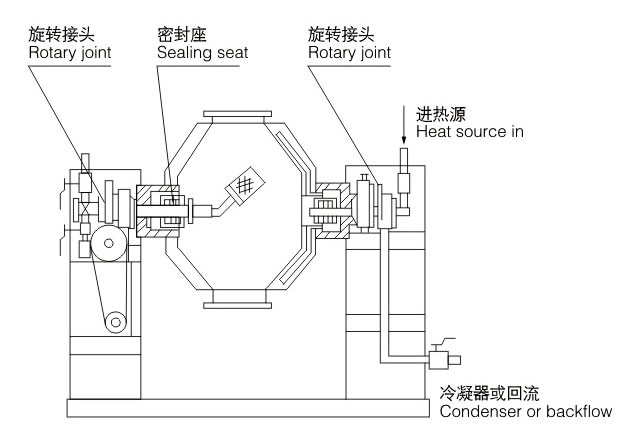

Principle of double cone vacuum dryer:

• After the heat source(such as hot water, low pressure steam or heat transfer oil) is connected to the closed jacket, the heat is transferred from the inner shell to the materials to be dried.

• Driven by the power, the tank makes slow rotation and the materials in the tank are continuously mixed so as to realize the purpose of drying.

• When the materials are under vacuum, the steam pressure reduces to make the moisture(solvent) on material surtaces reach the saturation status and evaporate, and discharged and recovered timely from the vacuum pump. The moisture(solvent) inside the materials is penetrated, evaporated and discharged towards the surfaces. The three processes are carried out continuously, so that the materials are dried within a very short time.

Features:

• During oil heating, automatic constant temperature control is adopted to dry biochemical products and mineral raw materials.

Temperatures vary within the range of 20-160℃.

• The heat efficiency is 2 times higher than that of common ovens.

• Indirect heating will cause no pollution to the materials, conforming to GMP requirements. The equipment is simple to repair and operate and easy to clean.

Drawings:

Technical Parameter:

| Model | SZG-100 | SZG-200 | SZG-350 | SZG-500 | SZG-750 | SZG-1000 | SZG-1500 | SZG-2000 | SZG-3000 | SZG-4000 | SZG-5000 |

| Total Volume (L) | 100 | 200 | 350 | 500 | 750 | 1000 | 1500 | 2000 | 3000 | 4000 | 5000 |

| Working Volume (L) | 50 | 100 | 175 | 250 | 375 | 500 | 750 | 1000 | 1500 | 2000 | 2500 |

| Heating Area (m²) | 1.16 | 1.5 | 2 | 2.63 | 3.5 | 4.61 | 5.58 | 7.5 | 10.2 | 12.1 | 14.1 |

| Rotation Speed (rpm) | 6-9 | 6-9 | 6-9 | 6-9 | 6-9 | 6-9 | 6-9 | 5 | 4 | 4 | 4 |

| Power (kw) | 0.75 | 1.1 | 1.5 | 1.5 | 2 | 3 | 3 | 4 | 5.5 | 7.5 | 7.5 |

| Rotation Height (mm) | 1810 | 1910 | 2090 | 2195 | 2500 | 2665 | 2915 | 3055 | 3530 | 3800 | 4180 |

| Machine Weight (kg) | 825 | 1050 | 1350 | 1650 | 1800 | 2070 | 2250 | 3000 | 4500 | 5350 | 6000 |

| Design Pressure in the tank (Mpa) | -0.09-0.096 | -0.09-0.096 | -0.09-0.096 | -0.09-0.096 | -0.09-0.096 | -0.09-0.096 | -0.09-0.096 | -0.09-0.096 | -0.09-0.096 | -0.09-0.096 | -0.09-0.096 |

| Design Pressure in the jacket( Mpa) | 0.03 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 |

Product Categories : Drying Machine > Double-Cone Rotary Vacuum Dryer

Home > Products > Drying Machine > Double-Cone Rotary Vacuum Dryer > Double Cone Rotary Vacuum Dryer for Chemical Products

Send Inquiry

Ms. Susan

Tel:86-0510-86184255

Fax:

Mobile Phone:+8615961650796

Email:susanliu35@gmail.com

Address:No.8 Dongmeng Road, Dongmeng Technology Zone, Nanzha Town, Jiangyin , Wuxi, Jiangsu

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.