Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Products

Brand: Jirui

Barrel Volume (L): 1000

Material: Sus304, Sus316, Sus316l

Application: Medicine Processing, Chemicals Processing, Food Processing, Powder

Old And New: New

Place Of Origin: China

Warranty Period: 1 Year

Core Selling Point: Automatic

Out-of-warranty Service: Video Technical Support, Online Support, Spare Parts

Applicable Industry: Manufacturing Plant

Marketing Type: New Product 2020

Mechanical Test Report: Provided

Video Factory Inspection: Provided

Core Component Warranty Period: 1 Year

Core Components: Motor

Warranty: 1 Year

Video Outgoing-inspection: Provided

Warranty Of Core Components: 1 Year

Key Selling Points: Competitive Price

Function: Mixer Blender

Material Processed: Chemicals, Food, Medicine

Place Of Origin: Jiangsu, China

Brand Name: Jirui

Applicable Industries: Manufacturing Plant, Food & Beverage Factory, Farms, Energy & Mining, Pharmaceutical industries

Packaging: Standard export wooden cases

Productivity: 10 sets/month

Transportation: Ocean,Land

Place of Origin: China

Supply Ability: 10 Sets/Month

Certificate: CE, CCC

Port: shanghai port

Payment Type: T/T,L/C

Incoterm: FOB,CFR,CIF,FCA

Features of Automatic Lifting Barrel Blender: 1.The original proportional position sensor makes the equipment safe and reliable, and will not cause equipment accidents due to misoperation.2.The Powder Blending Machine is equipped with an exquisite hopper that fully meets the requirements of GMP, and the discharge does not leave any residue, and it is easy to clean.

Principle of Double Column Lift Hopper Mixer :

This Double Column Automatic Lifting Hopper Blender is composed of machine base, rotary body, driving system, braking system and control system. When working, push the mixing hopper into the rotary body, press the "confirm" button on the touch screen, the mixing hopper can be automatically lifted to the position and clamped automatically. After the pressure sensor gets the clamping signal, it drives the mixing system to work. The mixing system mixes according to the set time and speed, and when the set parameters are reached, the rotating body can automatically stop vertically. At the same time, the braking system works and the mixing ends, and then the lifting system works. The mixing hopper in the slewing body descends to the position, automatically stops and prints the process data, and pushes out the mixing hopper to the next process.

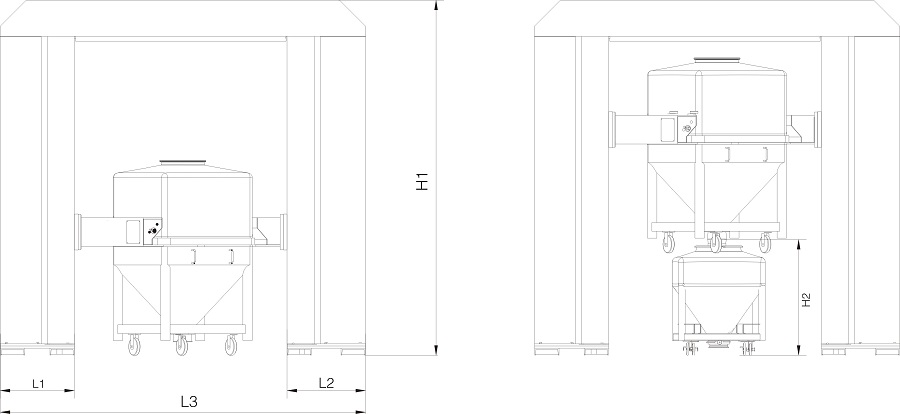

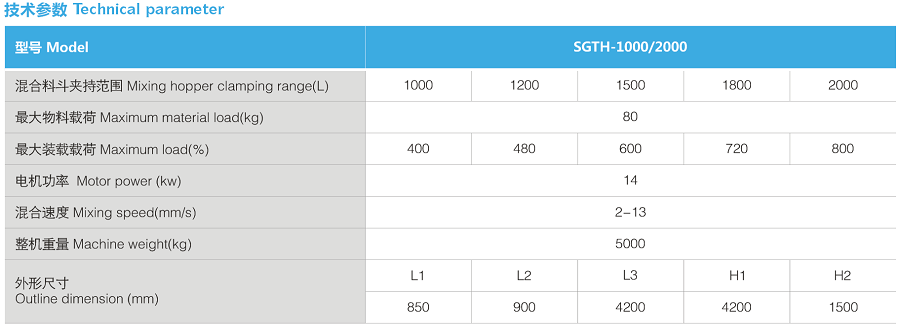

Drawing:

Pictures:

Product Categories : Mixing Machine > Double-Column Automatic Lifting Hopper Blender

Home > Products > Mixing Machine > Double-Column Automatic Lifting Hopper Blender > Automatic Lifting Hopper Barrel Mixer Blender Machine

Send Inquiry

Ms. Susan

Tel:86-0510-86184255

Fax:

Mobile Phone:+8615961650796

Email:susanliu35@gmail.com

Address:No.8 Dongmeng Road, Dongmeng Technology Zone, Nanzha Town, Jiangyin , Wuxi, Jiangsu

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.